REQUEST A QUOTE / ENQUIRY FORM

Vision Data Acquisition Software

Definitions and Datasets

Radiant's Precision Line of Test Systems are driven by Vision Software. Vision

Software is a framework that loads a variable series of independent agents known as

Tasks. Tasks are configurable objects that perform the procedures of an experiment

and collect and analyze any measured data. Such an experiment is called a Test

Definition.

The true power of Vision is in grouping Tasks together in Test Definitions to form

custom experiments (Datasets) so the user is not tied to running one specific task

at a time. The Test Definition may consist of any number of Measurement Tasks.

Researchers can create a dataset to hold any number of arbitrary Test Definitions

that are executed from inside the dataset to save and document the data forever.

Vision's "Innovative Test Editor" let's researchers create and document complex Test

Definitions using computer icons to represent Tasks.

Vision offers 115 Tasks in Total. Vision is the only software package available for

ferroelectric testers that provides exceptional freedom to design, conduct and

review all procedures associated with any material experiment. Vision dramatically

increases the productivity of the researcher, reducing the time required to acquire

data in an experiment. Vision’s enhanced productivity directly reduces cost of test.

Vision dramatically increases the complexity of the research that may be

accomplished by allowing researchers to combine different measurement tasks with

environmental controls into an automated test procedure managed by programmable

logic embedded with automated data collection, analysis and plotting tools.

• Waveform : Applies a sine, square, triangle or user-defined voltage waveform to stress the sample. The waveform is of user-defined voltage, frequency and duration.

• DC Bias : Applies a constant user-defined voltage to the sample for a user-defined duration.

Hysteresis - This Task measures sample polarization (μC/cm2‑) response to a Task-applied voltage profile. The profile is of user-specified maximum voltage and period (ms) (Period = 1000/frequency (Hz)). Profiles are normally standard bipolar (triangular), but may be monopolar, double-bipolar, sinusoidal or user-specified.

Small Signal Capacitance - This measurement captures the sample's capacitance as a function of voltage. It measures the capacitance at each voltage step using a very small stimulus signal to eliminate polarization -switching components of the sample response.

PUND - A standard five-pulse ferroelectric sample characterization measurement that captures both switching (remanent + non-remanent) and non-switching (non-remanent) polarization (‑μC/cm2). Pulse width and voltage are under user control.

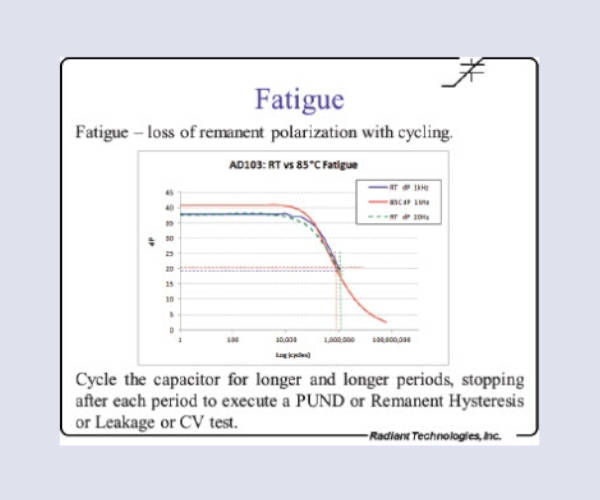

Fatigue - Performs a series of stress/measure sequences. In the stress sequence the sample is submitted to a switching waveform. At the end of the waveform period, a PUND measurement is made to capture the sample’s polarization response. Each subsequent stress period may have its duration increased to better serve a logarithmic analysis.

Leakage - Captures the current through a sample induced by a steady-state, DC Bias voltage. Voltage and measurement duration are user-defined.

Curve Energy - Determines the energy returned and the energy lost from a charged capacitor. It is useful for measuring power capacitors for new energy generating systems.

General Monopolar - The General Monopolar Task allows up to five independently configured monopolar Hysteresis measurements to be made in sequence in order to execute a PUND measurement using continuous waveforms. Each measurement may be preceded by an unmeasured presetting pulse or poling DC Bias period.

Magnetoelectric - Radiant's new Magnetoelectric Response Task allows the user to measure the magnetoelectric coupling coefficient in multiferroic materials and composite magnetopiezoelectric devices. The test stimulates a sample with a small AC magnetic field while measuring its charge generation.

Pyro-Electric - Sets the sample to a series of temperature by performing GPIB control of an external thermal device. At each temperature it captures the sample’s polarization response and/or small-signal capacitance. These are combined to calculate the pyroelectric coefficient.

Transistor - Radiant has introduced an I²C digital-to-analog converter product that can be attached to the Precision Premier II or Multiferroic Test System and is controlled from Vision. The addition of this extra voltage source makes it possible for the testers to measure the performance of thin-ferroelectric-film gate transistors (TFFTs and MFSFETs).

DLTS - Deep Level Trap Spectroscopy Task allows the user to measure the population of traps filled during a voltage pulse of a non-linear material and measure the decay rate of the trapped population as a function of temperature.

PAINT - PAINT was originally designed to capture the mechanical and acoustic vibrations induced in an ink jet chamber by the pulsing of the piezoelectric element to re an ink droplet. In reality, the PAINT Task in Vision can be used to capture the acoustic response of any activity, including SONAR type measurements in a water tank.

LCR Meter - This task allows the user to query an external LCR meter for its measurements including capacitance, loss, and Tan Delta.

Set Field - This task allows the user to specify a setting for the superconducting magnet connected to a Quantum Design 6000 controller.

Temperature - This Task sets the sample to a series of temperature by performing GPIB control of an external thermal device. At each temperature it captures the sample’s polarization response and/or small-signal capacitance. These are combined to calculate the pyroelectric coefficient.

Collect/Plot : Simple data collection and plotting.

Mathematical Analysis : Combine two measured data vectors into one through addition, subtraction, multiplication or division or perform single vector manipulation on one or more input data vectors.

Averaging : Average multiple data vectors together to form a single vector, average one or more single vectors with itself over multiple iterations in a Branch Loop or perform statistical analysis on one or more single vectors.

Data Mining : Invoking the data mining wizard allows the user to sort through all the Datasets on the computer to pull out and plot together any tests.

REQUEST A QUOTE

Hardware Tasks

These are Tasks that send signals to a tester through the driver and apply a voltage profile to the sample. These also may communicate with other instruments attached to the tester or to the host computer. Hardware Tasks normally apply a voltage profile to the sample. Testers may apply voltages of up to ±10 Volts, ±100 Volts, ±200 Volts, or ±500.0 Volts depending on tester model. Voltages of up to ±10,000 Volts may be applied with the addition of an accessory High-Voltage Interface (HVI) and High Voltage Amplifier (HVA). Hardware Tasks include:• Waveform : Applies a sine, square, triangle or user-defined voltage waveform to stress the sample. The waveform is of user-defined voltage, frequency and duration.

• DC Bias : Applies a constant user-defined voltage to the sample for a user-defined duration.

Measurement Tasks

These are Hardware Tasks that receive data from the tester. Measurement Tasks include, but are not limited to:Hysteresis - This Task measures sample polarization (μC/cm2‑) response to a Task-applied voltage profile. The profile is of user-specified maximum voltage and period (ms) (Period = 1000/frequency (Hz)). Profiles are normally standard bipolar (triangular), but may be monopolar, double-bipolar, sinusoidal or user-specified.

Small Signal Capacitance - This measurement captures the sample's capacitance as a function of voltage. It measures the capacitance at each voltage step using a very small stimulus signal to eliminate polarization -switching components of the sample response.

PUND - A standard five-pulse ferroelectric sample characterization measurement that captures both switching (remanent + non-remanent) and non-switching (non-remanent) polarization (‑μC/cm2). Pulse width and voltage are under user control.

Fatigue - Performs a series of stress/measure sequences. In the stress sequence the sample is submitted to a switching waveform. At the end of the waveform period, a PUND measurement is made to capture the sample’s polarization response. Each subsequent stress period may have its duration increased to better serve a logarithmic analysis.

Leakage - Captures the current through a sample induced by a steady-state, DC Bias voltage. Voltage and measurement duration are user-defined.

Curve Energy - Determines the energy returned and the energy lost from a charged capacitor. It is useful for measuring power capacitors for new energy generating systems.

General Monopolar - The General Monopolar Task allows up to five independently configured monopolar Hysteresis measurements to be made in sequence in order to execute a PUND measurement using continuous waveforms. Each measurement may be preceded by an unmeasured presetting pulse or poling DC Bias period.

Optional Tasks Include:

Piezo-Electric - Captures asample’s displacement as a function of voltage profile along with the sample’s polarization response. An external displacement measurement instrument must be attached to the tester to make this measurement.Magnetoelectric - Radiant's new Magnetoelectric Response Task allows the user to measure the magnetoelectric coupling coefficient in multiferroic materials and composite magnetopiezoelectric devices. The test stimulates a sample with a small AC magnetic field while measuring its charge generation.

Pyro-Electric - Sets the sample to a series of temperature by performing GPIB control of an external thermal device. At each temperature it captures the sample’s polarization response and/or small-signal capacitance. These are combined to calculate the pyroelectric coefficient.

Transistor - Radiant has introduced an I²C digital-to-analog converter product that can be attached to the Precision Premier II or Multiferroic Test System and is controlled from Vision. The addition of this extra voltage source makes it possible for the testers to measure the performance of thin-ferroelectric-film gate transistors (TFFTs and MFSFETs).

DLTS - Deep Level Trap Spectroscopy Task allows the user to measure the population of traps filled during a voltage pulse of a non-linear material and measure the decay rate of the trapped population as a function of temperature.

PAINT - PAINT was originally designed to capture the mechanical and acoustic vibrations induced in an ink jet chamber by the pulsing of the piezoelectric element to re an ink droplet. In reality, the PAINT Task in Vision can be used to capture the acoustic response of any activity, including SONAR type measurements in a water tank.

External Instrument Control

These are Tasks that communicate with remote instruments through a GBIP bus.LCR Meter - This task allows the user to query an external LCR meter for its measurements including capacitance, loss, and Tan Delta.

Set Field - This task allows the user to specify a setting for the superconducting magnet connected to a Quantum Design 6000 controller.

Temperature - This Task sets the sample to a series of temperature by performing GPIB control of an external thermal device. At each temperature it captures the sample’s polarization response and/or small-signal capacitance. These are combined to calculate the pyroelectric coefficient.

FILTERS

These are Tasks that collect, operate on, store and plot data from one or more Measurement Tasks or other Filters. Filter categories include:Collect/Plot : Simple data collection and plotting.

Mathematical Analysis : Combine two measured data vectors into one through addition, subtraction, multiplication or division or perform single vector manipulation on one or more input data vectors.

Averaging : Average multiple data vectors together to form a single vector, average one or more single vectors with itself over multiple iterations in a Branch Loop or perform statistical analysis on one or more single vectors.

Data Mining : Invoking the data mining wizard allows the user to sort through all the Datasets on the computer to pull out and plot together any tests.

REQUEST A QUOTE