REQUEST A QUOTE / ENQUIRY FORM

MICRACUT 200-S High Speed Precision Cutter

MICRACUT 200-S High Speed Precision Cutter 1

Cutting of various materials

Precision Cutting of PCB

precision-sectioning-pcb-electronic-components

MICRACUT 200-S High Speed Precision Cutter 1

Cutting of various materials

Precision Cutting of PCB

precision-sectioning-pcb-electronic-components

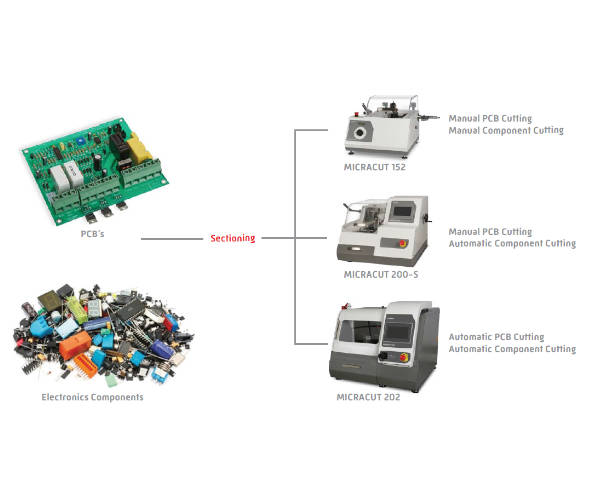

Using MICRACUT 200-S for Electronics & Semiconductors Sample Preparation

The MICRACUT 200-S is a powerful solution tailored for precise and deformation-free cutting of various materials.

When it comes to electronics and semiconductor sample preparation, the MICRACUT 200-S shines in several key areas:

- 1. High-Speed Precision Cutting:

- The MICRACUT 200-S offers semi-automatic grinding capability, allowing precise material removal from electronics and semiconductor samples.

- It ensures that delicate structures remain intact during the cutting process, crucial for maintaining sample integrity.

- 2. Angle Grinding Possibility:

- With the optional angle cutting arm, the MICRACUT 200-S enables angle grinding for specific applications.

- This flexibility is valuable when dealing with intricate geometries or specific material layers within electronic components.

- 3. Sample Types in Electronics & Semiconductors:

- Electronics and semiconductor samples fall into four main groups:

- Silicon Wafers: Used extensively in semiconductor manufacturing.

- Chip-Based Components: These include integrated circuits (ICs), transistors, capacitors, and resistors.

- Electronic Components: Such as connectors, diodes, and sensors.

- Printed Circuit Boards (PCBs): The backbone of electronic devices.

- The MICRACUT 200-S is particularly adept at handling these small, intricate samples with precision.

- Electronics and semiconductor samples fall into four main groups:

- 4. Sample Preparation Workflow:

- Cutting: When the inspection area lies deep within the sample, cutting can reduce the total grinding depth.

- Precision Sectioning: Obtain small pieces from large electronic specimens.

- Cold Mounting: Prepare the sample for subsequent steps

- Grinding: Precise grinding is the initial step to reveal hidden layers within the sample or focus on specific inspection areas.

- Polishing: After cutting and grinding, polishing removes scratches and enhances the microstructure for microscopic examination.

- 5. Unique Challenges in Electronics & Semiconductors:

- Multilayered Structures: Many electronic and semiconductor samples consist of different layers with varying materials (glass, plastic, metals, ceramics, etc.).

- Microscopic Scale: The structures within these samples are exceptionally small, demanding high-precision sample preparation equipment.

- Wire Bonding Techniques: Due to the tiny component size, specialized wiring techniques like wire bonding are often employed.

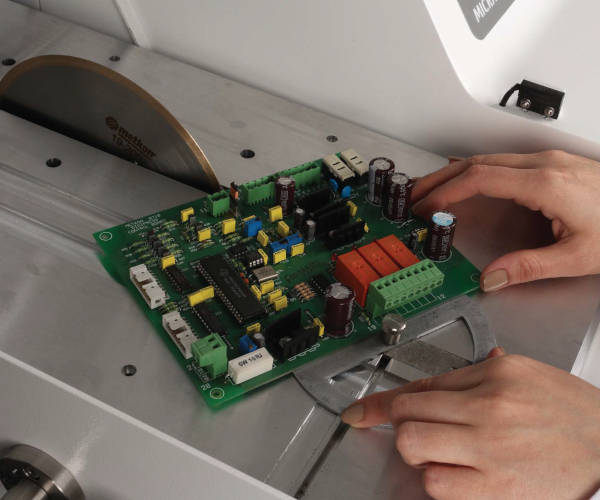

- 6. Efficient Removal of Electronic Components from PCBs:

- The optional cutting table attachments can be mounted on the MICRACUT 200-S.

- This feature allows easy and quick removal of electronic components from PCB boards by cutting them precisely using the MICRACUT 200-S.

In summary, the MICRACUT 200-S is an indispensable tool for electronics and semiconductor laboratories, ensuring meticulous sample preparation for accurate analysis and quality control

| Cut-off Wheel Diameter, (mm) | up to Ø200 mm |

| Cutting Capacity, Ø (mm) | Ø75 mm |

| Sample Movement in Z-Axis | Manual |

| X-Axis Positioning Range, (mm) | 0 - 50 mm |

| X-Axis Positioning Accuracy, (μm) | 5 μm |

| Cutting Feed Speed, (μm/s) | 5 - 10000 μm/s |

| Cutting Motor Power, (kW) (S1) | 0.55 kW |

| Disc Speed, (RPM) | 100 – 5000 RPM |

| Control Panel | 7" HMI Touch Screen |

| Program Capacity | 99 Program Memory |

| Cutting Modes | Automatic Cutting in Z-Axis Manual Cutting in Z-Axis Manual Table-Feed Cutting in Y-Axis |

| Pulse Cutting | Yes (Rapid Pulse Cutting) |

| Automatic Feedrate | Yes (Instafeed Cutting) |

| Multi-Section Cutting | Yes (Hybrid Cutting) |

| Parallel Cutting, X-Axis | Yes (Semi-Automatic) |

| Precise Grinding Feature | Yes (Manual/Semi-Automatic) |

| Grinding Wheel Diameter, (mm) | Ø175 mm |

| Grinding Feed Speed, (μm/s) | 500 - 50000 μm/s |

| Cooling Unit, (l) | 4.5 l (integrated) |

| Illumination | LED |

| Dressing During Cutting Operation | Yes |

| Motor Drive System | Direct Drive |

| Dimensions, W x D x H, (mm) | 640 x 732 x 529 mm |

| Weight | 90 kgs |

| Cutting Tables for MICRACUT 200-S | |

| GR 0215 | Fixed Cutting Table Attachment for manual cutting of extra flat specimens and PCB 's on MICRACUT 200-S including angle cutting tool and parallel slicing tool. 288x460 mm table size, cutting capacity is up to 200x200x35 mm (WxDxH) for flat specimens. |

| GR 0216 | Movable Cutting Table Attachment for manual cutting of extra flat specimens, sheet metals and PCB 's on MICRACUT 200-S including angle cutting tool, and parallel slicing tool. 288x300 mm table size, 220 mm movement range in Y-axis. cutting capacity is up to 170x200x35 mm (WxDxH) for flat specimens. |

| GR 0223 | Vertical clamping fixture for Movable Cutting Table |

| YM 1590-00 | Dressing Stone |

| Specimen Vises for MICRACUT 200-S | |

| GR 0210 | Universal Specimen Vise for MICRACUT 200-S/202 |

| GR 0400 | Universal Specimen Vise |

| GR 0401 | Specimen vise with double parallel vice for long specimens. |

| GR 0402 | Specimen vise for round and mounted specimens, ø32mm |

| GR 0403 | Specimen vise for irregular shaped specimens. |

| GR 0404 | Specimen vise for adhering specimens. |

| GR 0405 | Specimen vise for biomedical samples. |

| GR 0430 | Specimen vise (teardrop shape) for specimens ø18-40mm. |

| GR 0431 | Specimen vise (teardrop shape) for specimens ø5-20mm. |

| GR 0434 | Specimen vise for round cylindrical specimens (max. up to 40 mm dia.) |

| GR 0406 | Swivel arm unit for angular cutting, MICRACUT 200-S |

| GR 0453 | Fastener vise for longitudinal sectioning of screws, fasteners tubes, etc. from 12 to 45 mm in length |

| Optional Flange Sets for MICRACUT 200-S | |

| GR 0410 | Set of Flanges, ø75 mm, suitable for 12,7 and 25,4 mm arbor dias. |

| GR 0411 | Set of Flanges, ø100 mm, suitable for 12,7 and 25,4 mm arbor dias. |

| MICRACUT 200-S | |

| Metkon Sample Preparation Solutions for Electronics Industry |