REQUEST A QUOTE / ENQUIRY FORM

MICRACUT 152 Precision Cutter

MICRACUT 152 Precision Cutter - Open

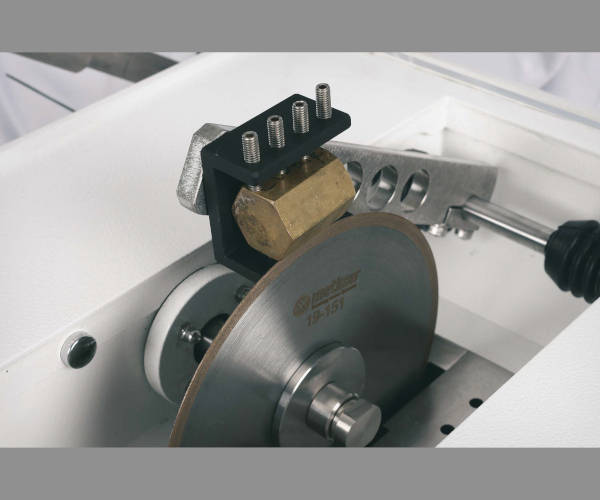

Variety of specimen vises are available

MICRACUT 152 Precision Cutter - Open

Variety of specimen vises are available

- Robust Design: The MICRACUT 152 boasts a modern and sturdy design, ensuring durability and longevity.

- High Precision Cutting: With a powerful 100 W DC cutting motor, this machine produces precise and deformation-free cuts.

- Easy Controls: The touch-pad controls with a digital display and ergonomic turn knob allow fast and easy parameter setting.

- Variable Speed: The disc speed ranges from 50 to 1500 RPM, providing flexibility for different materials.

- Sample Positioning: The digital micrometer cross feed allows accurate specimen positioning.

- Safety Features: Transparent protection hood with a magnetic safety switch ensures operator safety.

- Cooling System: The integrated recirculation coolant tank keeps the cutting process efficient.

| Disc Diameter, mm | Ø175 mm |

| Cutting Capacity, mm | Ø50 mm |

| Cutting Motor Power, W | 100 W |

| Disc Speed, RPM | 50 - 1500 RPM |

| Cutting Method | Chop |

| Parallel Cutting in X-Axis | Yes |

| X-Axis Positioning, mm | 25 mm |

| Cooling Unit, l | 850 ml (integrated) |

| Dimensions, WxDxH, (cm) | 40 x 41 x 36 |

| Weight, kgs | 28 kgs |

| Accessories for MICRACUT 152 | |

| GR 0213 | Cutting Table Attachment for manual cutting of extra flat specimens and PCB 's on MICRACUT 152 |

| GR 0409 | Dressing Unit for MICRACUT 152 |

| YM 1590-00 | Dressing Stone |

| Specimen Vises for MICRACUT 152 | |

| GR 0400 | Universal Specimen Vise |

| GR 0401 | Specimen vise with double parallel vice for long specimens. |

| GR 0402 | Specimen vise for round and mounted specimens, ø32mm |

| GR 0403 | Specimen vise for irregular shaped specimens. |

| GR 0404 | Specimen vise for adhering specimens. |

| GR 0405 | Specimen vise for biomedical samples. |

| GR 0430 | Specimen vise (teardrop shape) for specimens ø18-40mm. |

| GR 0431 | Specimen vise (teardrop shape) for specimens ø5-20mm. |

| GR 0434 | Specimen vise for round cylindrical specimens (max. up to 40 mm dia.) |

| GR 0406 | Swivel arm unit for angular cutting. |

| GR 0453 | Fastener vise for longitudinal sectioning of screws, fasteners tubes, etc. from 12 to 45 mm in length |

| GR 0410 | Set of Flanges, ø75 mm suitable for 12,7 mm Arbor dia. |

| Spare Part Kit for MICRACUT 152 | |

| GR 1960 | Recommended Set of Spare Parts, MICRACUT 152 |

| MICRACUT 152 |