REQUEST A QUOTE / ENQUIRY FORM

• NOVOTEST

UT-1M

• NOVOTEST

UT-1M

Test

• NOVOTEST

UT-1M Test

1

•

NOVOTEST

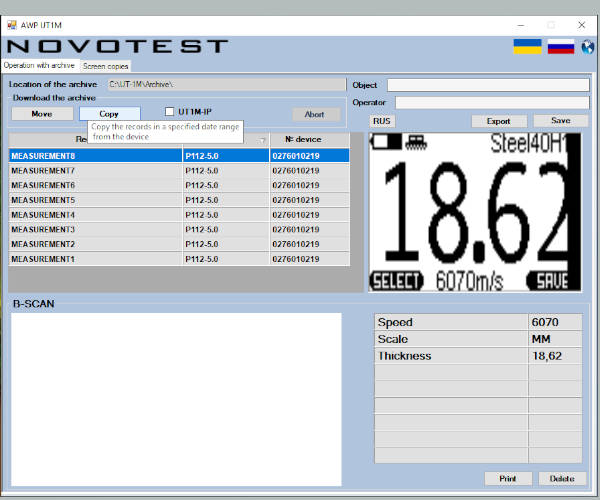

UT-1M

Software

- Wide measurement range of thicknesses

- Easy operation and setup

- Selection of the type of probe through single button

- Pre-set velocity of ultrasound

- Graphical display with backlight

- Compensation of probe delay

- Mapping the presence of acoustic coupling on the graphic display

- Fixation of the last measurement result in the removal of the transducer surface

- The device allows user to store the measurement results in the device, and subsequently transfer them to a PC using special software.

| Measuring Range (depending on sensor type), mm Probe 10MHz – P112-10-6 / 2 Probe 5MHz – P112-5-10 / 2 Probe 2,5MHz – P112-2,5-12 / 2 |

0.8 ... 300

(range 0.8-30mm) (range 1-75mm) (range 2-300mm) |

| Setting range of the ultrasonic velocity | 1000-9999 m/s |

| Discrete readings on the digital indicator | 0.1mm |

| Response time | Not more than 2s |

| The basic error of measurement, mm | ± (0,001 T+/- 0.1) |

| Overall dimensions | 120x60x25 mm |

| Operating temperature range | -5 to +40 ° C |

| Time of continuous work hours | Up to 10 hours |