REQUEST A QUOTE / ENQUIRY FORM

• NOVOTEST

UT-3M-EMA

• NOVOTEST

UT-3M-EMA

Test

• NOVOTEST

UT-3M-EMA Test

1

•

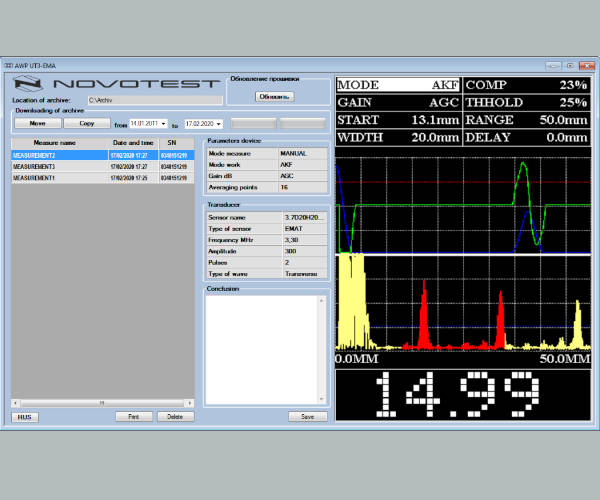

NOVOTEST UT-3M-EMA Software

- Unique automatic operation mode of the thickness gauge. The device automatically analyzes the measured signals, selects the required measurement method, adjusts the parameters of the receiving path and displays the measured thickness on the display. Therefore, even a new user will be able to accurately and easily measure the thickness of various products or metal samples under automatic operation mode.

- The device implements the B-scan mode, which allows user to get the product profile like a picture that is easy to read. Using a specialized carriage for the probe, it becomes possible to scan extended objects and obtain a thickness profile.

- There is expert control mode where user can carry out manual measurements using all known methods– using the autocorrelation function (ACF), measurement between two maximum signals in the gate, echo by zero crossing, echo-echo passing through zero.

- There is a special auto calibration mode available on a standard thickness sample.

| Thickness Measuring range for steel | 0.5 to 200mm |

| Permissible gap between device and testing object | Up to 6mm |

| Setting range of the ultrasonic velocity | 1000 - 9999 m/s |

| Operation modes |

|

| Duration of continuous operation hours | More than 8 hours |

| Operating temperature range | -20 to +50 ° C |