REQUEST A QUOTE / ENQUIRY FORM

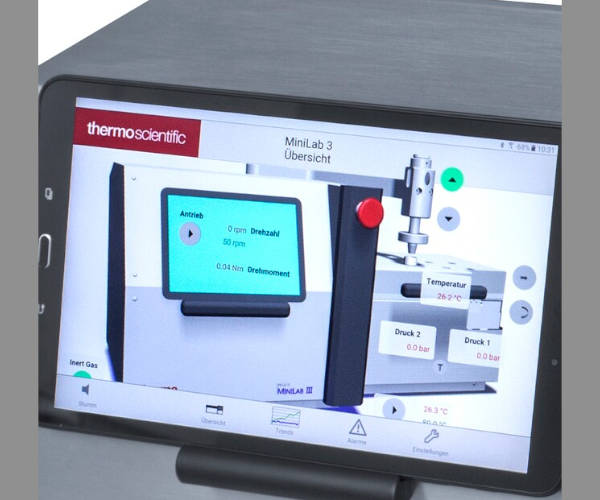

HAAKE™ MiniLab 3 Micro Compounder 1

HAAKE™ MiniLab 3 Micro Compounder 2

HAAKE™ MiniLab 3 Micro Compounder 3

HAAKE™ MiniLab 3 Micro Compounder 2

HAAKE™ MiniLab 3 Micro Compounder 3

| Rheology | Relative viscosity measurement |

| Speed Range | 1 to 400 rpm |

| Bypass | Pneumatic |

| Injection Pressure | Up to 300 bar |

| Max. Temperature | 350°C |

| Extruder Design | Conical |

| Max. Torque | 5 Nm |

| Screw Type | Co-/counter rotating |

| Electrical Requirements | 230V±10%, 50/60Hz |

| Specification Sheet – Haake MiniLab 3 |