Process 16 Parallel Twin-Screw Extruder

Enhance Efficiency in R&D and Small-Batch Production

Achieve optimal process development and cost-effective production with the Thermo Scientific™ Process 16 Parallel Twin-Screw Extruder.

This versatile extruder empowers researchers, developers, and manufacturers with superior performance for compounding, mixing, and shaping a broad range of materials.

Designed for Efficiency and Flexibility:

- Broad Throughput Range (0.4 kg/hr to 20 kg/hr): Process small or large batches efficiently, adapting to your specific needs.

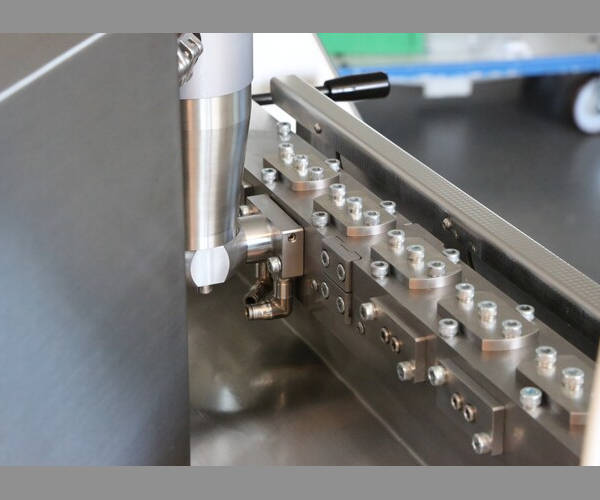

- Segmented Screw Design and Removable Top Half Barrel: Simplify cleaning, maintenance, and screw configuration changes for maximum workflow optimization.

- Fully Ported Barrel: Enables superior control over feeding and degassing for consistent, high-quality results.

- User-Friendly Touchscreen Control: Streamline operation with an intuitive interface for easy process control.

Unmatched Versatility for Diverse Applications:

- Wide Range of Accessories: Integrate feeders, dies, pelletizers, sheet take-off systems, and a filament spooler to suit your specific needs.

- Material Compatibility: Process various materials effectively with a choice of three contact part steel grades. Recommended materials are such as polymers, biopolymers, additives, adhesive, food and cosmetics.

- Scalable Screw and Barrel Design: Ensure seamless scale-up from R&D to pilot production.

- Hygienic version available: for food and pharmaceutical applications.

REQUEST A QUOTE / ENQUIRY FORM

SPECIFICATIONS

VIDEOS

BROCHURE

SPECIFICATIONS

| Barrel diameter | 16 mm |

| Barrel length | 40 L/D |

| Barrel/screw material | 440C – Process 16 Extruder X15TN – Process 16 Hygienic Extruder |

| Diameter ratio Do/Di | 1.78 |

| Screw speed | 10 … 1000 rpm |

| Torque max | 36 Nm |

| Pressure | 100 bar |

| Temperature | 350°C (optional 450°C) |

| Heating zones | 8 zones, 7 x 5 L/D electrical heated (optional water cooled) |

| Throughput range | 0.4 kg/h to 20 kg/h (material dependent) |

| Dimensions | 1230 x 690 x 1120 mm (L x W x H) |

| Weight | 180 kg |

VIDEOS

BROCHURE

| Process 16 Twin-Screw Extruder |

EXTRUDERS AND COMPOUNDERS

EXTRUDERS AND COMPOUNDERS

Menu