Energy 11 Twin-Screw Extruder

Revolutionize Your Battery R&D

The Thermo Scientific™ Energy 11 Twin-Screw Extruder empowers researchers to develop next-generation batteries with unparalleled efficiency. This innovative extruder tackles challenges in battery processing by delivering:

- Unmatched Mixing Efficiency: Achieve consistent, high-quality mixtures for your battery components through the extruder’s exceptional design.

- Reduced Solvent Usage: Significantly decrease solvent consumption during mixing – from 45% to as low as 15% – for substantial cost savings and eco-friendly processes.

- Broad Material Compatibility: The Energy 11 extruder seamlessly adapts to a wide range of battery materials, from dry granules and polymeric electrolytes to electrode films and wet slurries.

Designed for Flexibility and Control

The extruder’s key features ensure a streamlined R&D workflow:

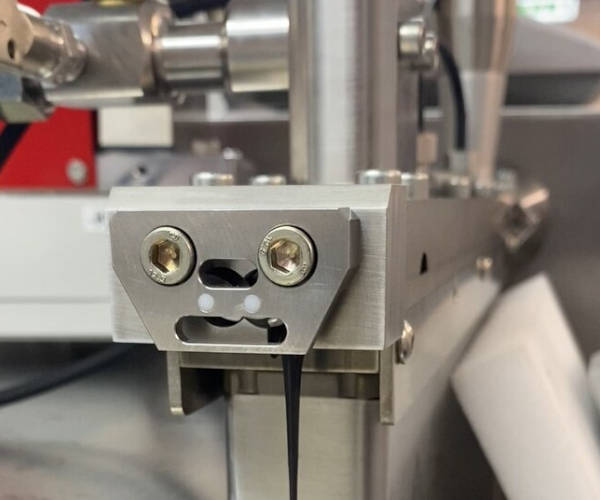

- Horizontally Split Barrel: This design allows for effortless feeding of both solid and liquid ingredients.

- Interchangeable Die Designs: Easily customize the extruder for various materials, optimizing your specific application.

- Precise Temperature Control: Eight independent temperature zones provide exceptional control over the processing environment.

Energy Savings and Scalability

The Energy 11 extruder isn’t just about efficiency in material handling. It also delivers significant energy savings:

- Reduced Drying Costs: Lower solvent use translates to less energy required for drying the final product.

- Scalable to Manufacturing: The extruder’s capabilities pave the way for a smooth transition from R&D to large-scale battery production.

REQUEST A QUOTE / ENQUIRY FORM

SPECIFICATIONS

APPLICATIONS

VIDEO

BROCHURE

SPECIFICATIONS

| Barrel diameter | 11 mm |

| Barrel length | 40 L/D |

| Barrel material | CPM 10V |

| Screw material | CPM 9V |

| Screw speed | 10 to 1000 rpm |

| Temperature range | 15 to 280 °C (8 individual zones) |

| Maximum torque | 6 Nm / shaft |

| Maximum pressure | 100 bar |

| Dimensions (L x W x H) | 890 x 490 x 425 mm |

| Weight | 70 kg |

| Power supply | 230 V, 16 A, 50/60 Hz |

APPLICATIONS

- Granulation

- Separator film extrusion

- Electrode slurry mixing

- Solvent reduced mixing

- Dry electrode processing

VIDEO

BROCHURE

| Specification Sheet – Energy 11 Twin-Screw Extruder |

EXTRUDERS AND COMPOUNDERS

EXTRUDERS AND COMPOUNDERS

Menu