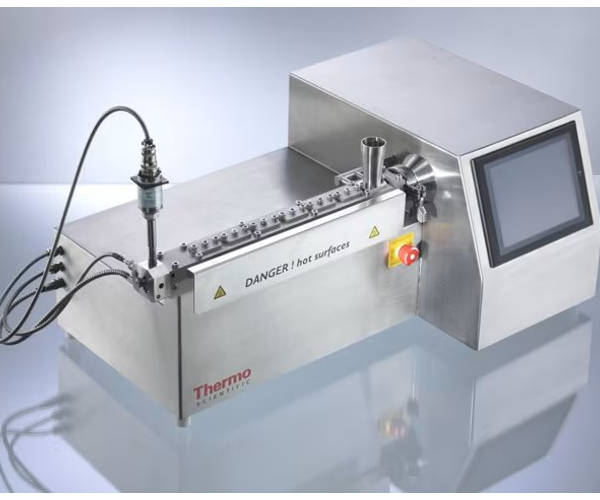

Process 11 Parallel Twin-Screw Extruder

Revolutionize Your Research with Efficient, Scalable Compounding: Introducing the Process 11 Parallel Twin-Screw Extruder

The Thermo Scientific™ Process 11 Parallel Twin-Screw Extruder is a game-changer for research and development labs. This innovative benchtop extruder empowers researchers to explore new formulations, optimize processes, and achieve faster development cycles with exceptional efficiency.

Key Features for Accelerated Innovation:

- Minimal Material Usage: The Process 11 excels in minimizing sample requirements, starting with just 20 grams per hour. This is ideal for researchers working with expensive or limited materials, allowing for cost-effective experimentation.

- Versatile Performance: Effortlessly tackle diverse compounding tasks with a wide range of feeding options and screw configurations. The Process 11 is suitable for various applications, including:

- Polymer compounding

- Food development

- Biomaterial processing

- Cosmetics research

- And more!

- Polymer compounding

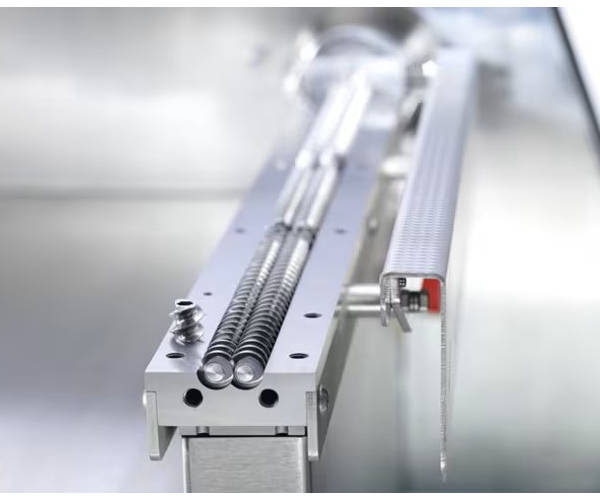

- Scalable Screw Design: The geometrically similar screw design ensures seamless scalability to larger Thermo Scientific extruders. This allows researchers to confidently translate successful lab formulations into pilot or production-scale processes.

- User-Friendly Operation: The intuitive touchscreen interface simplifies operation and minimizes training time. Researchers can focus on their experiments, not struggling with complex controls.

- Compact Footprint: Optimize valuable laboratory space with the Process 11’s space-saving design. This makes it ideal for crowded R&D labs where maximizing benchtop real estate is crucial.

- Complete Compounding Line Integration: Integrate the Process 11 with a complete compounding line offered by Thermo Scientific. This includes feeding solutions, downstream equipment like water baths, conveyor belts, pelletizers, and more, allowing you to create a comprehensive R&D workflow within a single platform.

Unleash the Potential of Your Research with the Process 11

The Thermo Scientific™ Process 11 Parallel Twin-Screw Extruder empowers researchers to achieve faster development cycles, explore innovative formulations, and optimize processes with exceptional efficiency.

REQUEST A QUOTE / ENQUIRY FORM

SPECIFICATIONS

VIDEOS

BROCHURE

SPECIFICATIONS

| Barrel diameter | 11 mm |

| Barrel length | 40 L/D |

| Barrel material | Nitriding steel 1.7365 (EN40B) |

| Screw speed | 10…1000 rpm |

| Torque per shaft | 6 Nm, constant torque, safety monitored. |

| Pressure | 100 bar, safety monitored |

| Temperature | RT…350°C (optional 450°C) |

| Feed zone | Permanently water cooled |

| Heating zones | 7 x 5 L/D electrical heated (optional water cooled) |

| Dimensions | 820 x 480 x 410 mm (L x W x H) |

| Weight | 55 kg |

| Power supply | 230 V, 16 A, 50/60 Hz |

VIDEOS

BROCHURE

| Specification Sheet – Process 11 Parallel Twin-Screw Extruder |

EXTRUDERS AND COMPOUNDERS

EXTRUDERS AND COMPOUNDERS

Menu