REQUEST A QUOTE / ENQUIRY FORM

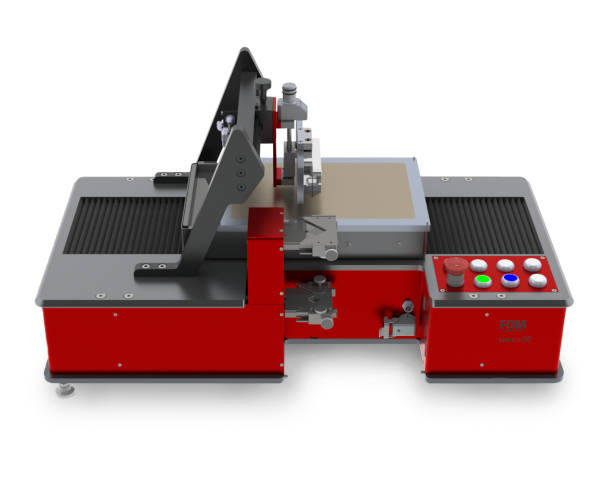

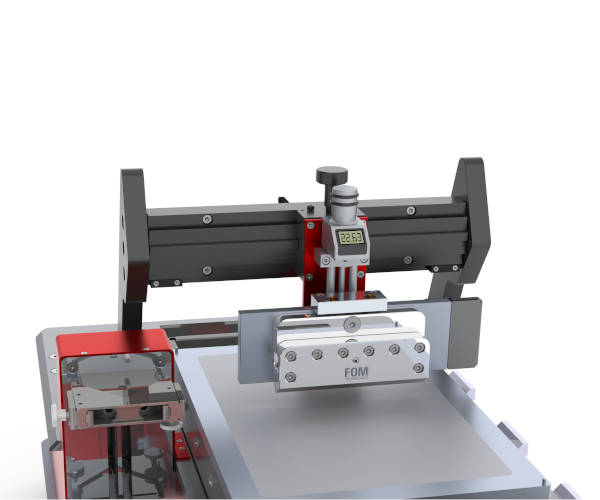

- Precision Control: Achieve unparalleled wet film thickness control and coat substrates up to 200mm wide. The intuitive laptop interface automates the coating process for repeatable, high-quality results.

- Versatile Substrate Handling: Seamlessly coat both rigid and flexible substrates with superior flatness and fixation, thanks to the precision-engineered microporous vacuum table.

- Optimized for Advanced Materials: The system is compatible with fluids of up to 20,000 cPs, and integrated substrate and slot-die head heating ensures optimal coating conditions for a wide range of materials.

- Scalable & Efficient: Produce uniform dry film thicknesses from tens of nanometers to hundreds of microns. The vectorSC offers high material efficiency compared to traditional blade and spin coating, and its technology is designed for simple, direct scaling from the lab to roll-to-roll production on the FOM moduloR2C.

- Glovebox Ready: Designed for seamless integration, the system is turnkey glovebox compatible, making it ideal for handling sensitive materials that require an inert atmosphere.

- Optional Atmosphere Control: An optional nitrogen/air knife module provides additional control over the coating environment.

The FOM vectorSC Slot Die Coater is widely used across multiple industries, including:

- Printed electronics and flexible displays

- Solar cell manufacturing

- Battery and energy storage devices

- Biomedical sensors

- Coatings for optics and packaging