REQUEST A QUOTE / ENQUIRY FORM

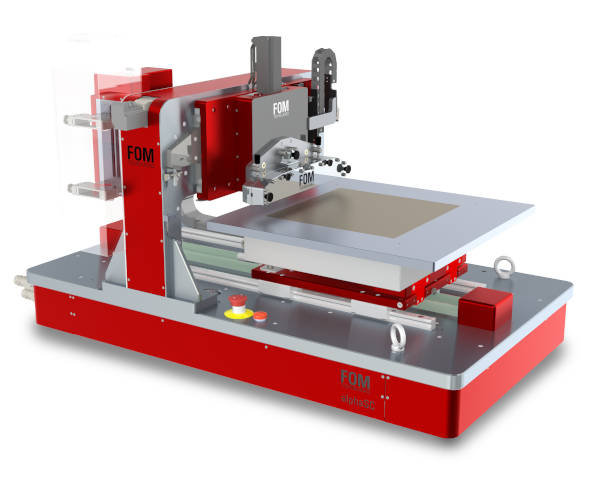

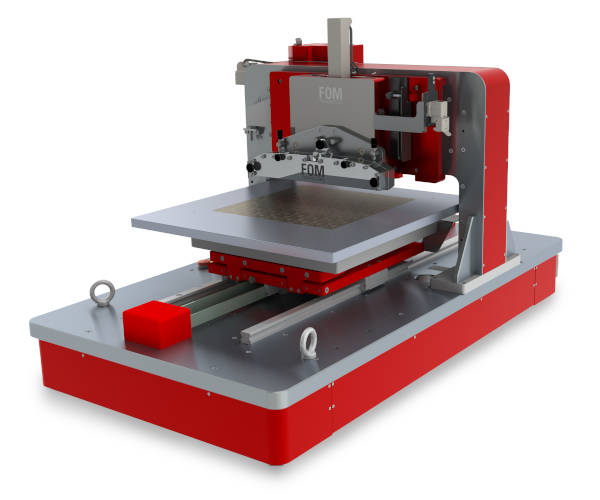

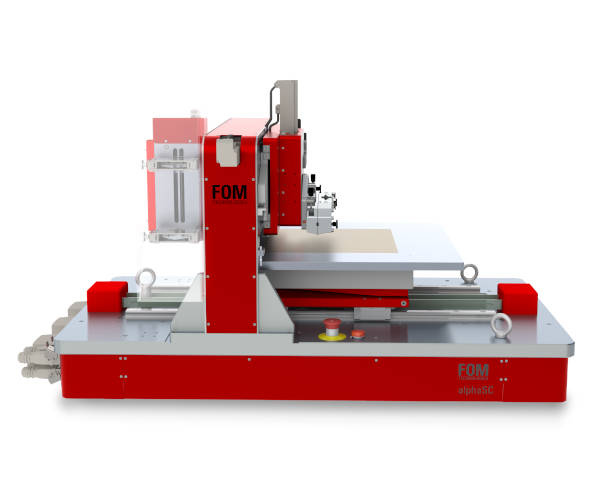

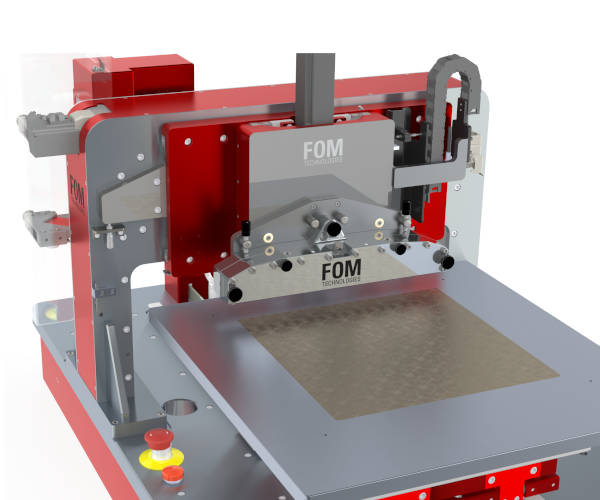

- Ultimate Precision & Reproducibility: The alphaSC is built on a foundation of high-precision, fully motorized motion systems with micron-level step control. This ensures impeccable coating uniformity and repeatable results, critical for systematic experimental design and data integrity.

- Versatile Substrate Compatibility: Effortlessly coat both rigid and flexible substrates up to 300 mm in width. The high-flatness microporous vacuum chuck provides excellent fixation and flatness, a crucial factor for defect-free films on a wide range of materials.

- Advanced Process Control: Go beyond basic coating. The alphaSC features integrated substrate heating up to 200°C and slot-die head heating up to 80°C. It is compatible with fluids with viscosities up to 20,000 cP, allowing you to work with a broad spectrum of research materials.

- Seamless Glovebox Integration: Designed for research with oxygen and moisture-sensitive materials, the alphaSC offers turnkey glovebox compatibility. Its compact, sheet-based design fits easily into an inert environment, protecting your valuable samples.

- Scalable "Lab-to-Fab" Approach: The alphaSC is the bridge between your lab and production. The coating protocols and processes developed on this system can be directly transferred to larger, roll-to-roll (R2R) production lines, such as the FOM moduloR2C, without extensive re-optimization.

- High Material Efficiency: Slot die coating is an inherently efficient technique. The alphaSC minimizes material waste, a significant cost-saving benefit when working with expensive or scarce novel materials.

- Modular Upgradability: Customize your system with optional modules, including an integrated oven for in-situ drying, a nitrogen/air knife module, and even flexo/microgravure modules for greater application versatility.

The FOM alphaSC is the preferred choice for leading research institutions and industry labs working on:

- Organic & Perovskite Solar Cells (OPVs & PSCs)

- Flexible and Printed Electronics

- OLED and QLED Display Technologies

- Battery and Fuel Cell Components

- Thin-Film Sensors & Membranes

- Functional Coatings for Smart Devices

- Nanomaterial Deposition