REQUEST A QUOTE / ENQUIRY FORM

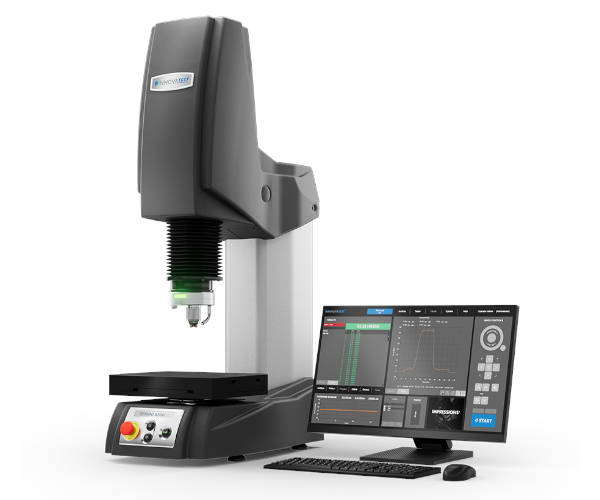

GEMINI 6200G2 (TRS, SRS)

| Scales | Rockwell, Superficial Rockwell, Brinell, HVD/HBD, Plastics & Carbon |

| Test Forces | 1 kgf – 250 kgf (load cell, closed loop force application system) |

| Load Application System | Fully automatic, load cell, closed loop, force feedback |

| Overview Camera | 13 MP stage overview camera, variable field of view |

| Display | 24” landscape mode capacitive touchscreen |

| Indenters | IRIS™ intelligent indenter system |

| Control | Integrated controller, i7 processor, Dual MSSD RAID storage or external PC |

| Laser | Cross laser positioning system |

| Illumination | Multi-color LED machine status indicator |

| Z-Axis | Descending test head, collision detection, CNC motorized (T model), ball bearing spindle, fast up/down & start buttons |

| Stages | Manual or motorized |

| Workpiece Height | Short version (S): 150 mm, Tall version (T): 300 mm |

| Output | XML, CSV, Q-DAS certified (optional) |

| Software | Wide range of software features, plug-ins, add-ons, Q-DAS certified |

The GEMINI 6200G2 is designed for precision hardness testing across a wide range of industries, including:

- Aerospace - Aircraft engine components and structural parts.

- Automotive - Testing of vehicle parts and assemblies.

- Production Lines - Inline quality control and process monitoring.

- General QA & Material Certification - Reliable hardness testing across metals and alloys.

- Research Laboratories - High-standard R&D applications requiring ultimate accuracy.